Ingress Protection Testing: Common IP Levels & Their Meanings

In the automotive industry, ensuring the durability and reliability of electronic components is crucial. Environmental factors such as dust, rain, mud, snow, and high-pressure washdowns can compromise electrical systems, leading to failures, safety hazards, or costly repairs.

Therefore, Ingress Protection (IP) testing plays a critical role in verifying that automotive components can withstand harsh environments — including dust, water, and other contaminants. Whether it’s switches, connectors, or lighting systems, IP testing ensures the reliability and safety of electrical parts installed in vehicles.

For example, products such as the C2-3027 Series, C2-3010 Series, and C2-388 Series are engineered to meet the rigorous standards of automotive and industrial applications. They feature high-level IP protection ratings, ensuring consistent performance even in harsh off-road environments such as rain, mud, and dusty conditions.

In this article, we will explore:

- What ingress protection testing is and why it matters.

- Common IP rating levels and their meanings.

- How testing is performed and key standards for compliance.

- Practical automotive applications and product examples.

- Guidance for selecting the right IP rating.

- Frequently asked questions about IP testing.

1.What Is Ingress Protection (IP) Testing?

Ingress Protection (IP) testing is a standardized method to evaluate the resistance of an enclosure to dust and water intrusion. Defined by the IEC 60529 standard, IP testing is widely recognized globally, particularly in regions like the United States, Europe, the U.K., and Australia.

The IP code uses two digits to indicate protection levels:

- First digit (0–6): Protection against solid objects, including dust and sand.

- Second digit (0–9K): Protection against water, ranging from light splashes to high-pressure jets and immersion.

For example, an IP67 rating means the component is completely dust-tight and can withstand temporary immersion in water up to 1 meter. Similarly, IP69K products can endure high-pressure, high-temperature water jets, making them suitable for heavy-duty automotive,industrial, and marine applications.

2.Why Ingress Protection Testing Matters in Automotive Applications

Modern vehicles contain numerous sensitive electronic components, including:

- ECUs (Electronic Control Units): Control engine, brakes, and vehicle electronics.

- Lighting systems: Headlights, fog lamps, and LED work lights.

- Connectors and enclosures: Critical for safe electrical connections.

Without proper IP testing, exposure to dust, moisture, or high-pressure washdowns can lead to:

- Electrical short circuits.

- Corrosion or material degradation.

- Reduced lifespan and unexpected failures.

Product Examples:

- C2-7303A:The C2-7303A features a fully IP67-rated enclosure designed to prevent water and dust ingress during heavy rain, off-road travel, or daily exposure to debris. This robust sealing ensures long-term reliability for stop, tail, indicator, and reverse functions. Its IP protection makes it ideal for commercial vehicles that require dependable performance in harsh outdoor environments.

- C2-7619:The C2-7619 is built with advanced sealing technology and an IP67 waterproof rating, preventing moisture, mud, and water splashes from affecting the lamp. Since fog lamps are mounted low and face constant exposure to road spray, the IP67 protection ensures stable illumination and prevents internal condensation. This makes it suitable for passenger cars, trucks, and specialty vehicles.

- C2-7127:The C2-7127 integrates multiple rear lighting functions within an IP67-rated housing that prevents water jets and dust intrusion. Its reinforced waterproof structure ensures that safety-critical functions—stop, tail, indicator, and reverse—remain reliable in all weather conditions. This high IP durability makes it ideal for trucks, trailers, agricultural machinery, and utility vehicles.

- C2-388 Series & C2-3028 Series:Engineered to meet IP69K standards, suitable for heavy-duty vehicles and equipment exposed to high-pressure cleaning.

3.Understanding the IP Code Structure

The IP code consists of two numbers that specify the level of protection:

| Digit | Meaning | Typical Automotive Application |

| First (0–6) | Protection against solids | Dusty dashboards, sensor enclosures, connector housings |

| Second (0–9K) | Protection against liquids | Rain, splashes, immersion, high-pressure washdowns |

- X indicates a category has not been tested.

- Example: IP67 = Dust-tight (6) + Immersion up to 1 meter (7)

- Example: IP68 = Dust-tight (6) + Continuous immersion beyond 1 meter (8)

- Example: IP69K = Dust-tight (6) + High-pressure, high-temperature water jets (9K)

4.Common IP Ratings Explained

IP65 – Dust Protected & Water Spray Resistant

- Application: Vehicle interior switches, non-exposed electronics, LED indicators.

- Protection: Resistant to dust and low-pressure water jets.

- Product Example: C2-936 Series is IP65-rated, offering reliable protection against dust and low-pressure water jets. Designed as a LED rechargeable headlamp, it provides durable illumination for construction sites, workshops, and outdoor tasks where both portability and weather resistance are essential.

IP67 – Dust-Tight & Temporary Immersion

- Application: External connectors, LED work lights, underbody sensors.

- Protection: Full dust protection; temporary immersion up to 1 meter.

- Product Example: The C2-391W auxiliary ambient lamp features an IP67 waterproof and dustproof rating, allowing it to perform reliably on boats, marine foredecks, or outdoor work areas where moisture, spray, and vibration are constant challenges. Its compact structure and robust sealing ensure dependable illumination even in harsh seaside environments.

IP68 – Long-Term Immersion Protection

- Application: Off-road vehicle electronics, EV battery modules, submerged sensors.

- Protection: Continuous immersion in water beyond 1 meter.

- Product Example: C2-3028 Series is certified IP68, ensuring stable operation in wet or muddy environments.

IP69K – High-Pressure, High-Temperature Water Resistance

- Application: Heavy-duty trucks, agricultural machinery, industrial vehicles.

- Protection: High-pressure, high-temperature water jets (up to 80°C).

- Product example: The C2-388 Series is engineered with a high-level IP69K protection rating, making it suitable for heavy-duty vehicles that undergo intense, high-pressure cleaning. Its reinforced housing ensures the lamp remains unaffected by water jets, mud, or dust—ideal for agricultural machinery, construction equipment, and rugged industrial applications.

Further Reading:

IP67 vs IP68: Waterproof Rating Comparison and Selection

C2-388 Series Agriculture Work Lights: Enhancing Efficiency in Modern Farming

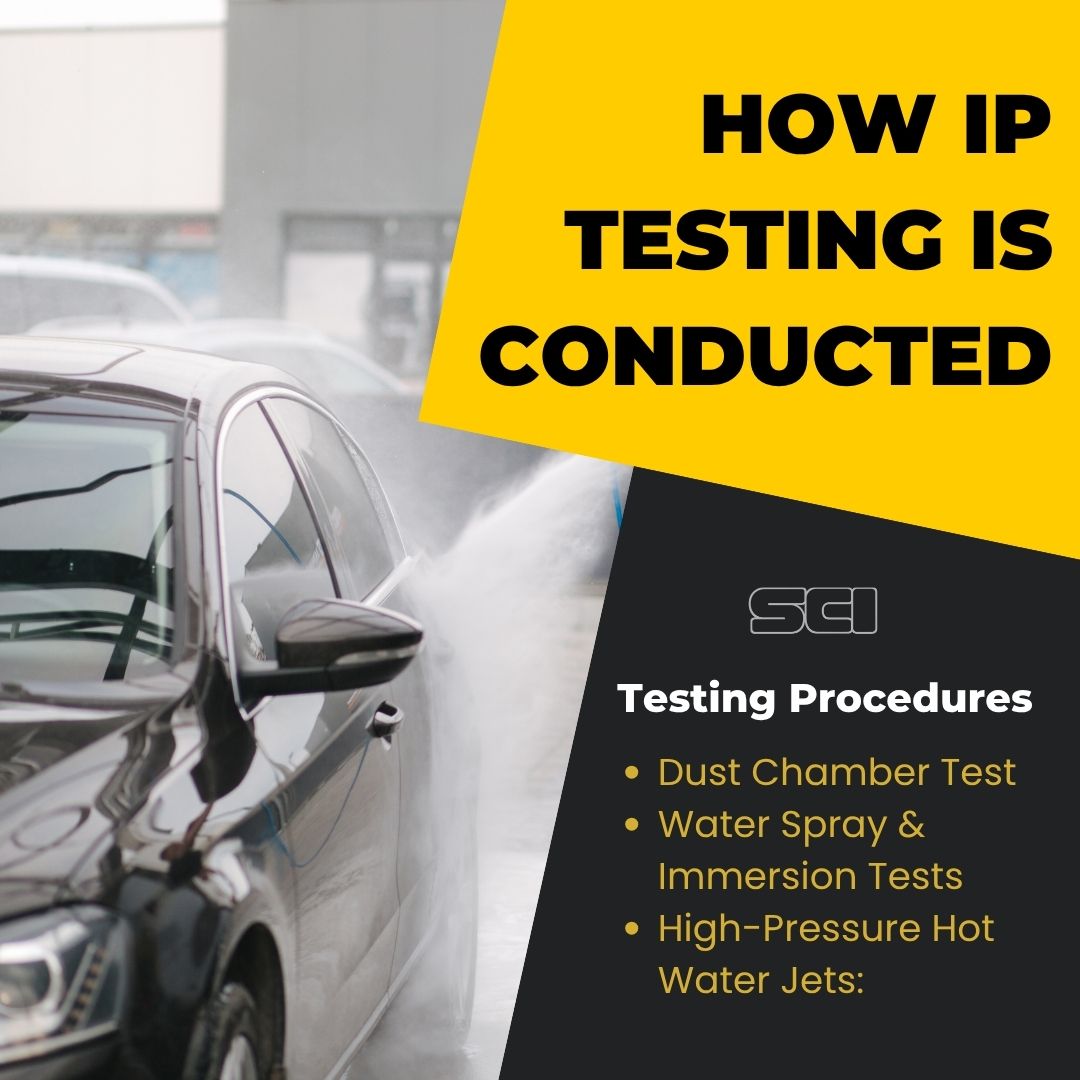

5.How IP Testing Is Conducted

Testing Procedures:

- Dust Chamber Test: Exposes components to fine dust particles to verify solid ingress protection.

- Water Spray & Immersion Tests: Simulates rain, splashing, or submersion under standardized conditions.

- High-Pressure Hot Water Jets: Used for IP69K-rated components, simulating industrial cleaning or washdowns.

Standards & Certifications:

- IEC 60529 – Global IP standard

- ISO 20653 – Automotive-specific ingress protection

- NEMA 250 / UL 50E – U.S. enclosures

- BS EN 60529 – European & UK compliance

- Accredited laboratories (ISO/IEC 17025) provide official IP test results and certification.

All SCI C2 Series products undergo rigorous IP testing in certified labs to ensure compliance with automotive industry standards.

6.Choosing the Right IP Rating

Consider the following when selecting an IP level:

- Environment: Outdoor vs. indoor, wet vs. dry, chemical exposure

- Installation Area: Underbody, engine bay, cabin interior

- Component Usage: Frequency of handling, exposure to cleaning or splashes

- Cost vs. Protection: Higher IP rating may increase manufacturing cost

Matching C2 Series products to IP requirements ensures both performance reliability and regulatory compliance:

- IP65→ C2-936 Series、 C2-933 Series

- IP66→ C2-922 Series、 C2-923 Series

- IP67→ C2-391Series、C2-7303A Series、C2-3003Series、C2-7208 Series

- IP68→ C2-388 Series、C2-392Series 、C2-528 Series、C2-530Series

- IP69K→C2-3010 Series 、C2-3028Series 、C2-392Series 、C2-7618、C2-7619

7.Ingress Protection Testing: Frequently Asked Questions (FAQ)

Q1: What is the difference between IP67, IP68, and IP69K?

- IP67: Dust-tight, temporary immersion

- IP68: Dust-tight, continuous immersion

- IP69K: Dust-tight, high-pressure hot water resistant

Q2: Why is IP testing critical for automotive sensors and switches?

- Protects electronics from moisture and dust

- Extends product life and prevents electrical failures

- Ensures regulatory compliance for international markets

Q3: Can the same IP rating be applied to all vehicle components?

They will not be the same. The choice depends on the level of environmental exposure in the intended application.

Q4:Can IP testing enhance customer trust?

Yes. SCI’s C2 series products, with IP certification, demonstrate exceptional reliability, enhancing customer confidence in automotive, industrial, and marine applications.

Ingress protection testing is essential for automotive component reliability, durability, and safety. Products like the C2-388 Series, C2-392 Series, and C2-7303 Series exemplify the importance of IP compliance in ensuring long-term performance across challenging environments.

Selecting the right IP rating, understanding standards, and working with accredited test labs ensures your products not only survive harsh conditions but also meet international regulatory requirements.

“Looking for certified IP testing or IP-rated automotive components? Contact our team today to ensure your products meet global ingress protection standards.”

Further Reading:

What Is UL Certification? Essential for Global Market Compliance