COB LED VS SMD LED Portable Work Lights: 8 Main Differences

If you’re finding LED portable work lights, you’ll likely see two types of light sources — COB and SMD. What’s the difference between them?

Let’s compare COB LEDs vs. SMD LEDs, breaking down 8 key differences, so that you can choose the right option for your automotive lighting.

COB LED vs. SMD LED Overview

If you search “COB LEDs vs. SMD LEDs”, you may know that they’re two of the most common LED designs you’ll see today. Here’s a quick look at each technology:

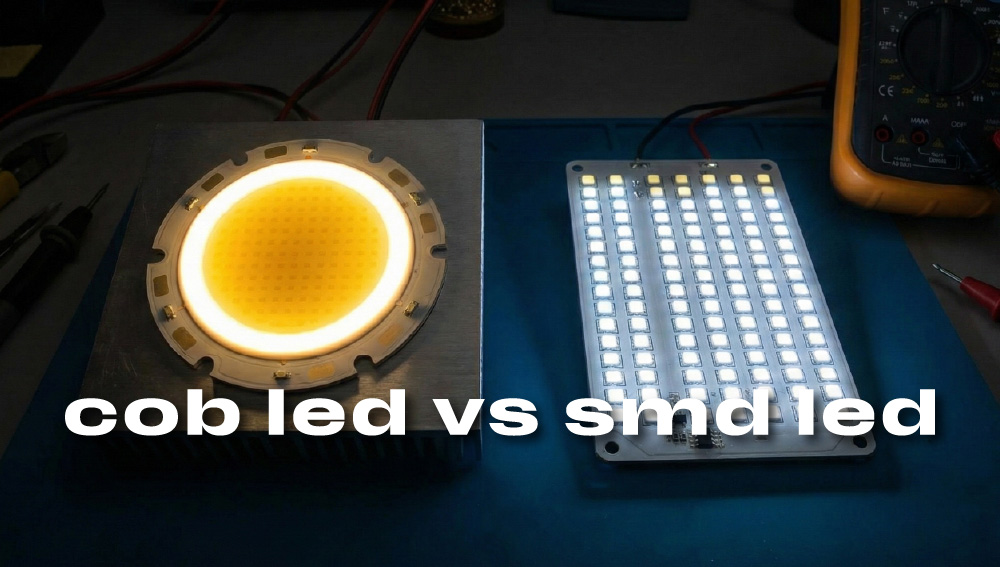

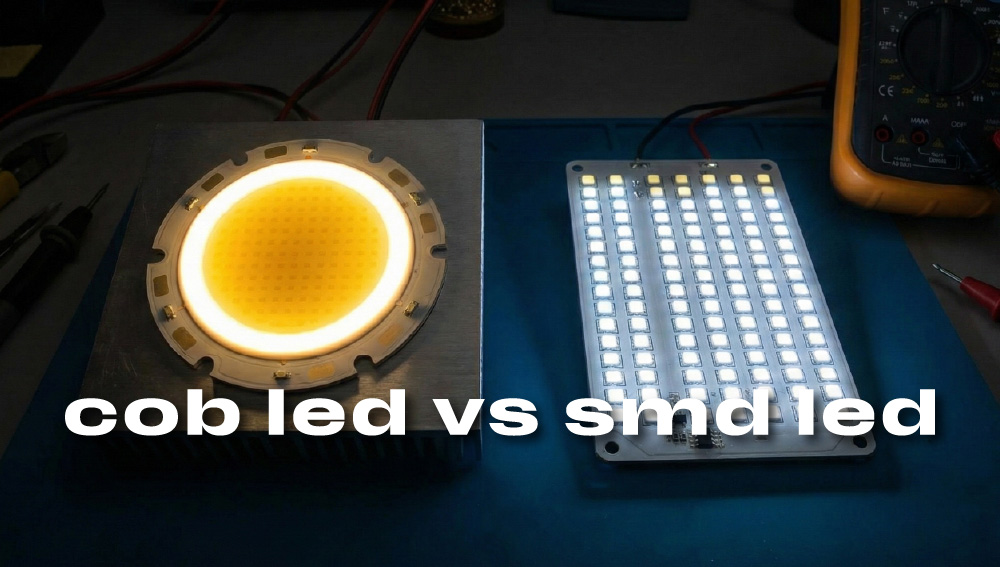

COB LED

COB (Chip-on-Board) LEDs consist of multiple small chips mounted on a single board. These LEDs feature several LED dies bonded directly onto an aluminum or ceramic substrate, which is then covered by a uniform layer of phosphor.

SMD LED

SMD (Surface-Mounted Device) LEDs place individual chips directly onto a printed circuit board (PCB). These chips are soldered onto a PCB using automated surface-mount technology (SMT). This setup makes them more versatile and energy-efficient.

SMD LEDs can be mounted on flexible or rigid PCBs, making them ideal for handheld lights with compact or curved housings, where uniform illumination and low heat buildup are required.

Further reading: Lux vs Lumens vs Candelas: Complete Guide for Vehicle Lighting

How Do COB and SMD LEDs Compare?

COB and SMD LEDs may look similar at first, but they differ in these 8 key ways:

Technology

The primary difference between COB and SMD LEDs lies in their construction. COB LEDs are made up of multiple chips mounted directly onto a single substrate, while SMD LEDs consist of individual diodes soldered onto a PCB.

Brightness

COB LEDs produce a powerful, concentrated light source. Their output is intense, typically measuring around 80–100 lumens per watt (lm/W).

SMD LEDs have lower lumen density but higher brightness efficiency. High-quality SMDs typically reach 100–120 lm/W, with advanced models exceeding 150 lm/W.

Light Source

COBs produce a single, uniform light source. To the human eye, this looks like one smooth beam. SMD LEDs offer better control and adaptability. This makes SMD a more versatile solution for products that require both brightness and design freedom.

Beam Angle

Due to their chip arrangement, COB LEDs produce narrower beam angles. SMD LEDs can achieve beam angles of 120 degrees, which allows for broader and more even illumination.

Further reading: A Guide to Understanding the Beam Angle of LED Lights

Energy Use

COB LEDs consume more electrical power to maintain their concentrated brightness. The tight placement of chips generates more heat, so if they aren’t cooled properly, they’ll consume more electricity.

On the other hand, SMD LEDs are known for their excellent energy efficiency. Their spaced-out chip layout facilitates better heat dissipation, leading to higher lumens per watt (lm/W) ratings and less energy loss.

Temperature

The compact design of COBs makes them more prone to overheating. They require a stronger cooling system to maintain stability, as failing to do so can result in reduced brightness and a shorter lifespan. In contrast, SMD LEDs have excellent thermal management capabilities, helping them maintain consistent performance over time.

Flexibility

SMD LEDs provide enhanced versatility in applications due to their modular design, which simplifies controlling brightness, arranging layouts, and mixing colors. This gives designers greater freedom to create products in various sizes, shapes, and light distributions.

Size

COBs tend to be larger because several chips are combined into one, while SMDs are compact, lightweight, and ideal for space-limited designs.

Further reading: Automotive Fog Lights: When to Use and Why They Matter?

Where to Find Quality SMD LED Products?

When choosing SMD LEDs, consistency and reliability matter just as much as performance. That’s why many businesses worldwide choose SHIN CHIN INDUSTRIAL (SCI).

With decades of experience in lighting technology, SCI offers a comprehensive range of LED products built for efficiency and durability.

Our portable LED floodlight (C2-923) is lightweight and easy to carry, featuring an IP66-rated lamp, making it ideal for construction site lighting. We also offer the C2-913D portable inspection lamp, perfect for large vehicle or machinery repair, with multi-stage brightness adjustment and a total light output of 800 lumens, suitable for industrial operations and outdoor activities.

From portable inspection lamps to automotive lighting, we provide dependable solutions at competitive prices — combining exceptional lighting performance with practical functionality.

Not sure what you’re looking for? Our responsive technical support team is ready to assist you from selection through installation, helping you find the right products for your application.

Get in touch with us today to explore our full product lineup.

Further reading: 5 Types of Boat Lights at Night and How They Keep You Safe

FAQs

Q1. What are the disadvantages of COB LED?

Although COB LEDs provide powerful light beams, they generate more heat due to the tight arrangement of chips. So, they require stronger cooling systems; otherwise, the excessive heat can affect luminous efficiency and cause brightness decay over long-term use.

Q2. Which is better, COB or SMD LED?

It depends on the application. COB LEDs are best for focused, high-lumen lighting needs, typically used in commercial indoor lighting products. In contrast, SMD LEDs provide superior adaptability for diverse installations such as automotive lighting and portable lamps, ensuring excellent performance and reliability.

Q3. Which type of LED is best for the eyes, COB or SMD LEDs?

Both COB and SMD LEDs are safe when manufactured to standard. Typically, COBs are gentler on the eyes because they provide a smoother light beam with minimal glare and flicker. However, SMDs can be combined with diffusers to create a more comfortable glow.

Q4. What Are the Applications of COB and SMD LEDs?

COB LEDs produce uniform and soft light, making them ideal for indoor and commercial lighting applications. On the other hand, SMD LEDs have a much wider range of uses — from small indicator lights to large display screens. In automotive lighting, SMD LEDs are commonly used in headlights and taillights.

About the Authors

This article was written by the SHIN CHIN INDUSTRIAL technical team, whose members have over 10 years of experience in LED lighting design and manufacturing.

Further reading:

The 11 Kinds of Car Lights You Should Know: Functions & Tips in One Guide

3 Uses of Forklift Truck Blue Lights That Make Workplaces Safer